Qualified grinding balls supplier could maximize your grinding efficiency

Grinding balls supplier in China Since 1980'

Our Quotation process

Grinding balls Hardness

l Values

l How Specified

Steel Composition

l Current Specification

l Historical background

Our target is to understand the customer demands and quote in appropriate way

Supply System

HY Part of Steel# and Chemical composition & Hardness Standard of the grinding balls

Brand | Remarks | Chemical Composition (%) of Raw Material | ||||||

C | Mn | Cr | S | P | Si | Hardness (HRC) | ||

HY-1 | 45# | 0.42-0.50 | 0.7-0.8 | ≤0.25 | Max0.035 | Max0.035 | 0.17-0.37 | 48-56 |

HY-2 | 50Mn | 0.48-0.56 | 0.7-1.0 | ≤0.25 | Max0.035 | Max0.035 | 0.17-0.37 | 50-56 |

HY-3 | 60Mn | 0.57-0.65 | 0.7-1.0 | ≤0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 58-60 |

HY-4 | 65Mn | 0.60-0.70 | 0.90-1.2 | ≤0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 58-65 |

HY-5 | 75Mn | 0.72-0.92 | 0.9-1.2 | ≤0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 55-65 |

HY-6 | B2 | 0.72-0.85 | 0.7-1.2 | 0.42-0.85 | Max0.030 | Max0.030 | 0.17-0.37 | 60-65 |

HY-7 | B3 | 0.5-0.65 | 0.4-1.0 | 0.77-1.10 | Max0.030 | Max0.030 | 1.4-1.8 | 60-65 |

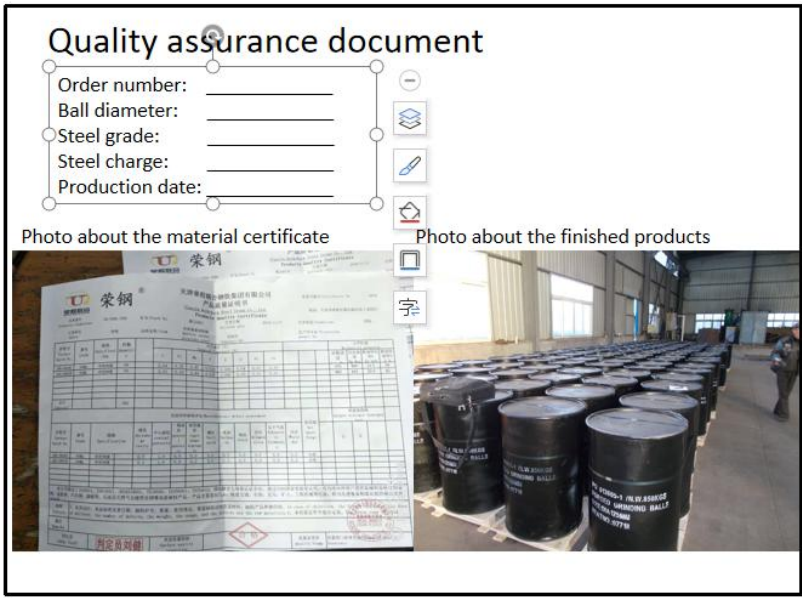

Material Assurance

Analysis certificate

l The steel certificate must be delivered to HY together with the batch steel

l Inspection department must confirm that the steel certificate and the steel bar label are the same

l Heating number from the material certificate is linked to HY documents in file for Customer tracking

Production Management System

Forging Grinding balls by Air hammer Hot rolling grinding balls

Grinding balls Mechanical Performance

*Steel: Low Carbon Steel, High Carbon and manganese Alloy steel, High Manganese Alloy Steel.

*Consistent Surface hardness to Core Hardness (58-65HRC)

*Grinding balls reach to the high Impact toughness more than 15J /cm2

*The lowest broken rate: 125mm Grinding balls have reached to "0" broken rate all less than 0.5%

*Improved wearing rates & toughness maximize the grinding efficiency of the mining and save cost

Grinding balls QC System

QC team-work : QC manager with more than 10 years’ experience in this industry and the team workers will test each batch grinding balls during production and inspection before delivery ( Surface & Core Hardness test , impact value and etc will be recorded in file according to different Steel Heating number , easily for future Tracking )

Packing System

Bags: Grinding balls could be packed in woven bags, 1000kgs per bag. On the pallets and effort in loading & unloading

Steel Drums: Grinding balls to be packed in steel drums with openable top ( with threads), the steel drums packed on pallets made of heat treated wood or plywood . Two drums on each pallet

China is the world's largest grinding media balls supplier . How to choose any better grinding media balls supplier in China ? We are trying to provide a different answers for your esteemed buyer .

---------------Trustworthy Product and Partner ( Grinding Balls Supplier in China )

Honest ppl , excellent quality ,reasonable price and best service enable Haoyang to be the trustworthy supplier of many customers from America, Canada, Chile, Korea and some other countries in the world specialize in the Cement, Mining ,Power plant and any other related industries on a global scale.

-----------Mature and innovative technology

Technical director of HY have been in the industry of grinding balls for more than 30 years with rich experice and all the technical team are professional workers in the forging industry to study the grinding media improvement and heating treatment technique for different industries.Focus on research and development, our grinding media balls quality have got reputable recognition from Gold Mining , Cooper mining , cement plant and any other related industries.

--------How to improve wear resistance of grinding balls to help you lower the cost

>Customized Raw Materials-Purchasing qualified raw material from China famous and standard Steel mills. The quality of the grinding steel balls is directly related to the raw materials. The chemical composition elements matching plays a key role in the performance of the grinding steel balls. Each batch of steel into factory willbe reinspected and consistant with steel mill certification.All the batches of qualified steel will be recorded in file and could be tracked via Heating Number during 5 years.

>Advanced Hot rolling production line and traditional labor forging combination enable all the specification from DIA20-150mm grinding balls could be supplied by HY , keep the stable grinding efficiency .

>Unique Heating treatment technique greatly influence grinding balls quality. Improve the surface and volume hardness , Hardness uniformity and toughness

>Strict Quality Control Systerm will be followed by each order during production and after production . Our Quality control Systerm will enable nearly 95% balls will be inspected before loading on board , lower your purchasing risk .