SAG Mill Grinding Balls Low Breakage

- HY

- China

- 20-45 days

- 50000T

SAG Mill Grinding Balls

HY mainly produce a range of grinding media balls in the mining and cement industry Application

1. Mining (Copper, Gold, Iron, Aluminum, Manganese, Zinc, Chrome etc. ), Cement Plant , Power station , chemical industry .

the Hot rolling grinding balls produced by advanced automatic rolling machine ( Grinding Balls from 20mm-70mm) + Labor Air Hammer ( 80mm-150mm) with special Heating treatment and strict quality control systerm , which make our grinding balls high performance

Grinding balls 'Raw Material Purchase : Strategic partnership with standard steel enterprise and sign the long term agreement (50,000 Tons annually ) Purchase directly from Chinese famous standard steel enterprise , such as laigang Group, HBIS, ANSTEEL, XIWANG Special steel .

We have special department of QC teamwork .The QC department director have 10 years experience in this industry . The team is responsible for inspection during production , inspection before delivery .( Forged Steel Grinding balls Surface and core hardness test each day each batch and all will be recorded and filed in documents )

Grinding Media Balls For SAG Mill Specifications:

HY Grinding Media Balls are produced from High Carbon low alloy steel bars and then forged into grinding balls. The grinding balls are produced via Hot rolling machine or labor air hammer or Roll forging for larger diameter SAG balls

During production , we must control the chemistry and microstructure to reach the optimum wearing resistance and impact value . The diameter of grinding balls range from 3.5"-6" are classified as SAG grinding balls used in SAG mill operation.

Quality guarantee: Replacement of Broken grinding balls

Surface and Volumetric Hardness (Rockwell C):

Hardness (HRC) | ||||||||||||

Ball Diameter | Surface Hardness | Volumetric Hardness | ||||||||||

3.5"/90mm | 60-65 | 59-65 | ||||||||||

4"/100mm | 59-64 | 59-64 | ||||||||||

4.5"/120mm | 58-63 | 58-63 | ||||||||||

5"/125mm | 57-62 | 57-62 | ||||||||||

5.5"/140mm | 55-61 | 55-61 | ||||||||||

Selecting the best-quality grinding ball is a key step towards reducing your mining costs.

Talk to us about your grinding media requirements.

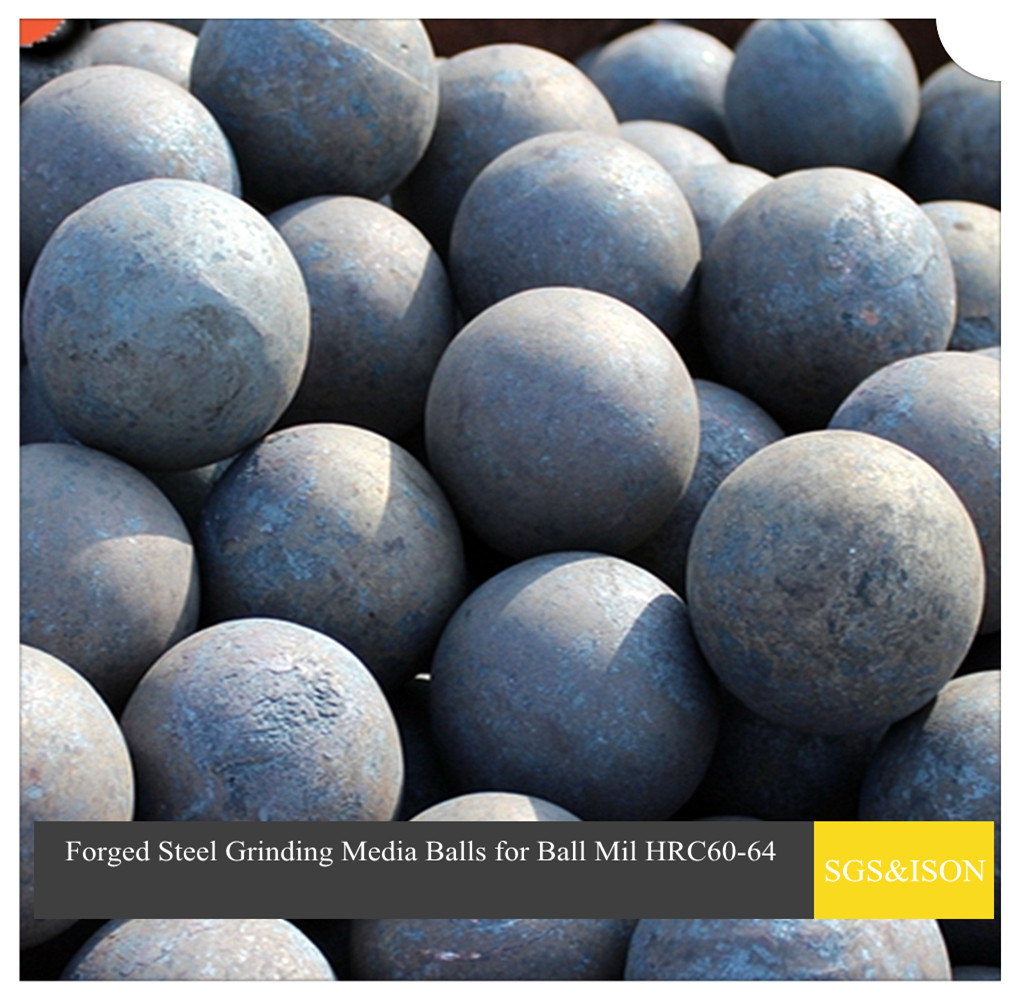

Forged Steel Ball Mill Balls

The size of forged grinding media balls from 20mm to 150mm are widely used in all kinds of mills in the mining industry ( Copper Mining , Gold mining and iron mine )![]()

Grinding Balls Features :

Steel : Low Carbon Steel , High Carbon and manganese Alloy steel , High Manganese Alloy Steel .

Consistant Surface hardness to Core Hardness ( 58-65HRC)

Grinding balls reach to the high Impact toughness more than 15J /cm2

The lowest broken rate : 125mm Grinding balls have reached to "0" broken rate ,all less than 0.5%

Improved wearing rates

Sizes: Haoyang manufactures grinding balls in nominal sizes from Dia25mm to Dia150mm. Grinding balls in the range of Dia 50mm to 125mm in diameter are classified as medium balls and are used primarily in ball mill operations.

Chemistry: An individual chemical profile has been developed for each diameter ball to correspond with the requirements for heat treatment. Specific alloy additions are included to produce optimum physical properties. The chemistry of the balls is controlled through a close collaboration with our bar suppliers and robust internal quality systems.

Surface and Volumetric Hardness (Rockwell C):

The wear resistance of the balls depends on the microstructure of the steel which is altered using carefully selected heat treatment variables specifically designed for each particular alloy. The control variable for the finish product is the hardness range.

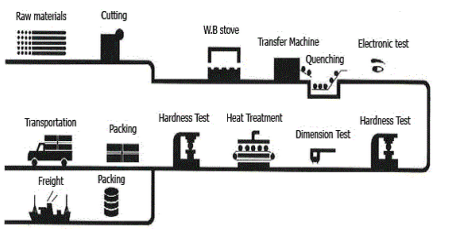

Grinding balls Production Line

Quality Production System

Grinding Media

P/O number , Batch and Date Recordings

1. Pre-production Checks : Steel bars (Diameter , Length of Cut bars, Heating Numbers signature ) Equipment includes

Air hammer Forging hammer , cooling time and Quenching time and etc..

Temperature Control :- Quenching start Temperature and Quenching End temperature . ( Produce 10 balls and then

Stop production )

2. Surface hardness measurement

Ball 1 ~~~ Ball 10 HRC Recordings

Surface Hardness Target

Materials : 60Mn

25-50mm >62 HRC

50-80 mm >60 HRC

90-125mm 56~~59 HRC

Material : B2

40-70mm >62 HRC

80-100mm 56~~60 HRC

110-140mm 52~~56 HRC

3. Core Hardness Test Store the 2 cut balls for further inspection

4. Heat Treatment before packing (Record Heat batch , Temperature)

5. Final Hardness Test before dispatch

Mark the hardness result in the grinding balls

Supply and Quality Guarantee

Long established strategic relationships with local and foreign raw material suppliers allow us to ensure all balls supplied to our customers are made from the highest quality products and meet strict specifications. This gives our customers a confidence in the quality of the product that Haoyang is able to assure.

Packing option

Bags: Balls can be supplied in woven bags , 1000kgs per bag,on the Pallets and effort in loading and unloading.

Steel Drums: grinding balls to be packed in steel drums with openable top (with threads),drums packed on pallets made of heat treated wood or plywood, two drums per pallet

Application Area

Mine

The ore grinding media usually comes out with the steel grinding ball and steel

Grinding rod. Its quality is the decisive factor affecting the operating cost of the mineral processing plant .

We could supply different steel grinding balls in line with different mines and diversified needs of the mineral processing plant. We can offer you the wear resistant steel grinding balls with the diameter ranging from 20mm to 140mm to fit for gold ore, Silver ore, cooper ore , iron ore, etc.. Those products get extensive promotion and applications in actual mining industry , and help the customers attain remarkable economic benefits by saying a lot of procurement cost and largely boosting the production output !

Cement Plant

The power consumption and steel consumption of the ball grinding mill occupy a rather high cost ratio in the production and processing process of a cement plant. The hardness , breakage rate and the corrosion resistance of the steel grinding ball affect the production cost and efficency of the ball grinding mill.

Electric Power Plant

The consumption of the steel grinding ball makes up the bulk of the operating cost in the electric power plant . It is very meaningful of how to find a way to reduce the cost and improve the efficiency .

Chemical And other Industries

We can according to the material to be groud provide the most appropriate wear resistant steel grinding balls to enhance the production efficiency of the ball grinding mill, and debase the production cost . Also availabe is the wear resistant steel grinding rod .

Haoyang have agent in Europe and providing grinding balls solutions for Gold mining . All the goods will be inspected in factory and then inspected in Loading

Port of china by SGS before loading on board . If unqualified , all the containers

Will be returned back to factory ! And we accept the claims caused by any problem of the steel .