Produce Cheap Grinding Steel Balls For Gold Mining Factory

- HY

- China

- 20-45 days

- 50000T

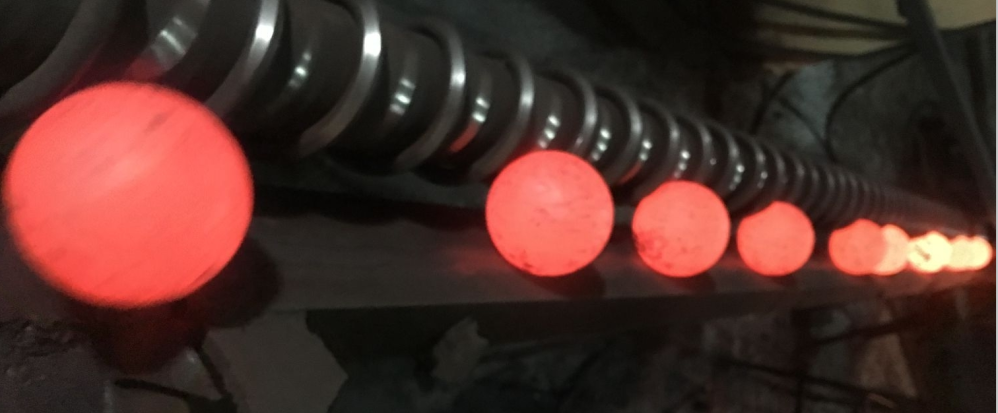

Our Grinding balls produced by advanced automatic rolling machine ( Balls from 20mm-70mm) + Labor Air Hammer ( 80mm-150mm) with special Heating treatment and strict quality control systerm , which make our grinding balls high performance

Grinding media balls 'Raw Material Purchase : Strategic partnership with standard steel enterprise and sign the long term agreement (50,000 Tons annually ) Purchase directly from Chinese famous standard steel enterprise , such as laigang Group, HBIS, ANSTEEL, XIWANG Special steel .

We have special department of QC teamwork .The QC department director have 10 years experience in this industry . The team is responsible for inspection during production , inspection before delivery .( Grinding balls Surface and core hardness test each day each batch and all will be recorded and filed in documents ) .

Produce Cheap Grinding Steel Balls For Gold Mining,Grinding steel balls Factory

HY specialize in the grinding steel balls industry for about 30 years and provide the best service for Gold mining ,copper mining and cement plant . The grinding balls are the means to crush or grind material ( mineral, coal or cement ) in the ball mill. So the grinding steel balls have different size and produced with different alloy steel under the working condition .

Application industry of Grinding steel balls

The size of forged grinding media balls from 20mm to 150mm are widely used in all kinds of mills in the mining industry ( Copper Mining , Gold mining and iron mine )![]()

The Features of Grinding balls :

Steel : Low Carbon Steel , High Carbon and manganese Alloy steel , High Manganese Alloy Steel .

Consistant Surface hardness to Core Hardness ( 58-65HRC)

Grinding balls reach to the high Impact toughness more than 15J /cm2

The lowest broken rate : 125mm Grinding balls have reached to "0" broken rate ,all less than 0.5%

Improved wearing rates

Steel Chemical composition :

| Brand | Remarks | C | Mn | Cr | S | P | Si |

| HY-1 | 60Mn | 0.57-0.65 | 0.60-0.70 | ≤0.25 | 0.030max | 0.030max | 0.17-0.37 |

| HY-2 | B2 | 0.72-0.85 | 0.7-1.2 | 0.42-0.85 | 0.030max | 0.030max | 0.17-0.37 |

| HY-3 | B3 | 0.5-0.65 | 0.4-1.0 | 0.77-1.10 | 0.030max | 0.030max | 1.4-1.8 |

| HY-4 | B4 | 0.58-0.66 | 0.65-0.80 | 0.70-0.9 | 0.025max | 0.025max | 1.3-1.9 |

Quality Assurance Systerm/ HY Grinding Steel balls / Grinding balls

1. Retained shape throughout test

2. The grinding balls are uniformly spherical in shape and no appreciable variation between two balls of the same diameter.

3. High impact strength: The grinding steel balls will not crack during operation .

4. Grinding steel balls strictly comply to the required standard alloy steel bar chemical composition .

5. The hardness of the grinding balls :

- Diameter : 90mm-150mm

Surface : 59-64HRC

Core: 58-63HRC

- Diameter: 60mm-80mm

Surface: 60-65 HRC

Core: 60-64HRC

- Diameter: 20mm-50mm

Surface: 62-66HRC

Core: 62-66 HRC

Grinding balls Packing : Steel drums with openable top (with threads). Two drums per pallet

Related Products